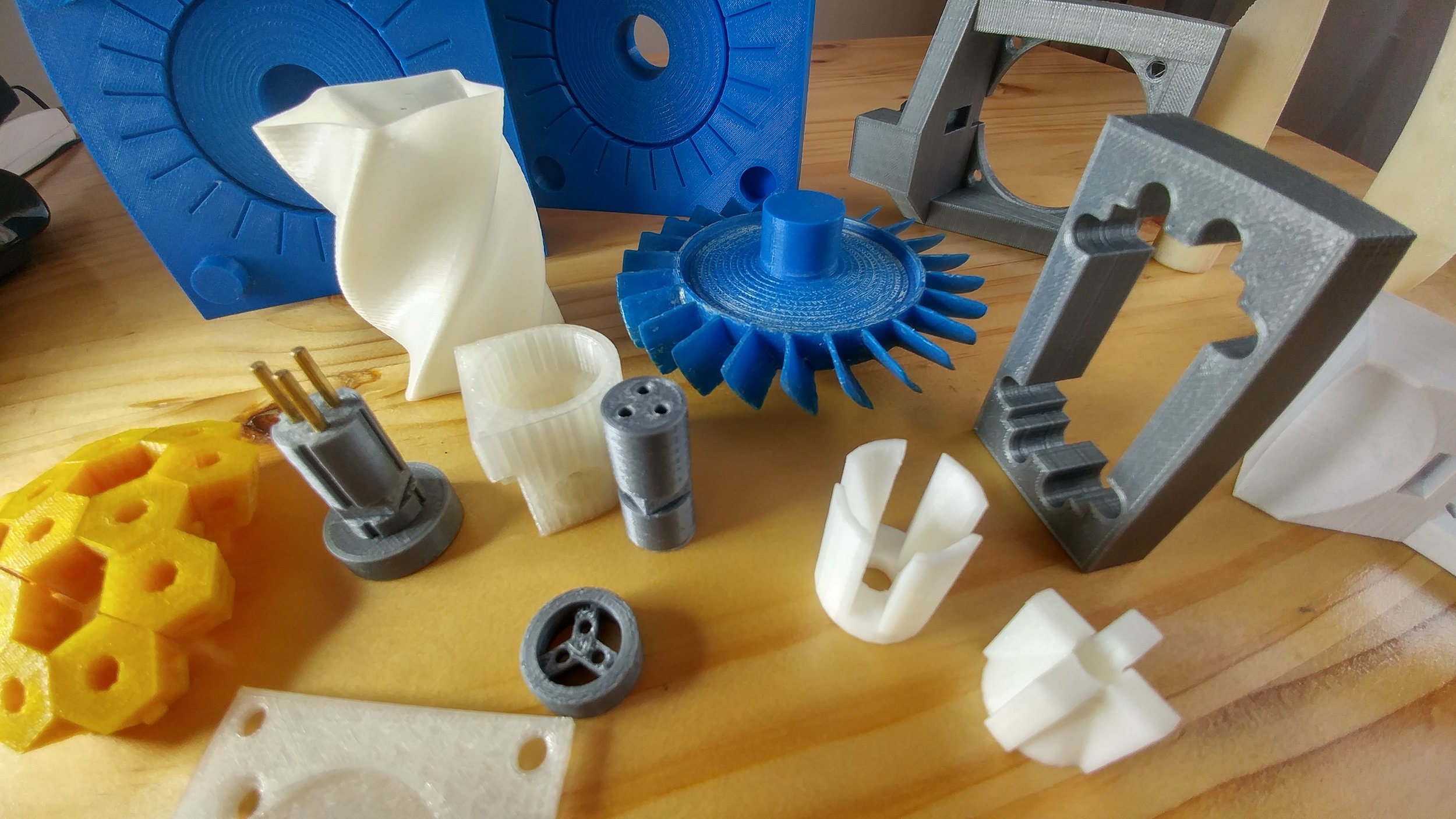

How Additive Manufacturing is Reshaping the Landscape of Spare Parts and Repair Services

Additive manufacturing is currently revolutionizing the realm of production and logistics. Among the countless areas of the field being transformed by 3D printing, its impact on spare parts and repair services is notably significant. This Tronix3D blog will discuss how additive manufacturing is reshaping the landscape and leading us toward a more sustainable and efficient future.

A Warehouse at Your Fingertips: On-Demand Printing of Spare Parts

Why stockpile spare parts when you can print them as needed? Additive manufacturing enables businesses to produce spare parts on demand, eliminating the need for large inventories. This not only reduces storage costs but also contributes to a more efficient supply chain. Consider the aviation industry, where companies like Airbus are using 3D printing to produce spare parts in-house, reducing wait times and improving service efficiency. The company’s 3D-printed parts are also said to be 15% lighter than their traditionally manufactured counterparts, decreasing production costs and further streamlining the process.

The Power of Precision: Enhanced Quality of Repair Parts

Additive manufacturing is not only about convenience; it's also about quality. 3D printing can produce parts with complex geometries that would be difficult or even impossible with traditional manufacturing methods. This opens up a world of new possibilities for repairing machinery or equipment that are otherwise irreparable. An excellent example of this is the automotive industry, where manufacturers like BMW are using additive manufacturing to create detailed components, allowing for more precise and effective repairs. BMW says the most valuable advantage of 3D printing is the degree of flexibility provided when building components with complex structures. High-quality vehicle parts with intricate details that could not be produced using conventional tools can be manufactured quickly and easily with additive manufacturing.

The Green Route: Promoting Sustainability Through Efficient Production

By printing parts only when needed, additive manufacturing minimizes waste, contributing to a more sustainable production model. Traditional manufacturing involves cutting away excess material, often creating waste in the process. Meanwhile, additive manufacturing adds material layer by layer, reducing waste and improving the overall sustainability of the project. According to the U.S. Department of Energy, additive manufacturing can decrease material usage by up to 90%, making it a more environmentally-friendly choice for spare parts production. This, in turn, improves energy productivity, which allows for greater design flexibility and reduced production time.

Greater Accessibility: Bringing Repair Services to Remote Locations

Transporting spare parts to remote locations can sometimes be a logistical challenge. With 3D printing, however, the production of spare parts becomes mobile. This means that spare parts can be produced almost anywhere, even in areas with limited access to traditional supply chains. The maritime industry, for example, has been exploring the use of 3D printing aboard ships to produce spare parts on the go, drastically reducing downtime caused by equipment failures. In 2022, The U.S. Navy partnered their spare parts suppliers with 3D companies in order to keep up with increasing demand. This translated into lower transportation costs, reduced wait times for parts, and fewer delays in cargo delivery.

Reinvigorating the Repair Culture: The Promise of Additive Manufacturing

Evidently, additive manufacturing is vastly altering the landscape of spare parts and repair services. Through on-demand printing, enhanced quality of repair parts, sustainable production, and greater accessibility, 3D printing is reinvigorating a culture of repair and extending the lifecycle of products. As this technology continues to evolve, it holds the potential to further streamline our supply chains, reduce waste, and bring about a more sustainable and efficient future in the realm of spare parts and repair services.

About Tronix3D

Tronix3D is a leading contract-based Additive Manufacturing company dedicated to providing exceptional low-volume production and prototype parts for a diverse range of industries. Our comprehensive services encompass mechanical design and consulting, specifically tailored to the unique requirements of additive manufacturing. Leveraging cutting-edge printing technologies such as HP Multijet Fusion (HPMJF), Fused Deposition Modeling (FDM), and Stereolithography (SLA), we deliver high-quality, precision-engineered solutions for our valued clients in the robotics, energy, medical, and defense sectors. At Tronix3D, we pride ourselves on our commitment to innovation, quality, and customer satisfaction, ensuring that our partners receive the best possible results for their projects. Discover more about our services and capabilities at www.tronix3d.com.