Innovative Products Made Possible by 3D Printing: A Showcase of Additive Manufacturing's Potential

From medical marvels to architectural wonders, the potential of 3D printing seems limitless. This transformative technology has given birth to a plethora of innovative products that were once the stuff of science fiction. Today, let's delve into the realm of additive manufacturing and explore some extraordinary products brought to life by 3D printing.

Constructing Dreams: 3D Printed Buildings

Photo credit: Apis Cor

When it comes to construction, additive manufacturing is pushing the boundaries. The likes of ICON and Apis Cor have stunned the world with their 3D-printed houses, demonstrating how 3D printing can revolutionize the building industry by reducing costs and construction time. These homes, created through advanced 3D printing technology, showcase exceptional architectural and energy-saving designs that highlight the advantages of durability and eco-friendliness while harnessing the potential of additive construction in the digital realm.

The Healing Touch: 3D Printed Prosthetics

Photo credit: Open Bionics

Through 3D printing, personalized prosthetics have become affordable and accessible. Companies like Open Bionics are harnessing this technology to create custom-fit prosthetics, providing a lifeline for individuals worldwide. Making this shape by hand would pose considerable challenges, but utilizing a 3D printer makes this feat a lot easier. By incorporating intricate frame designs into the “Hero Arm,” the weight of this prosthetic has been reduced by 30-50%.

Culinary Innovation: 3D Printed Food

Photo credit: Foodini

Believe it or not, 3D printing has made its way into our kitchens. Companies like Foodini are making headlines by 3D printing food, from intricate chocolate designs to healthy snacks. The device employs open capsules into which users can load their preferred food ingredients, as long as they fit the right texture. It can print a wide range of dishes, including both savory and sweet options, unlike some 3D printers that are restricted to only making candies. Foodini automates certain aspects of the cooking preparation process, like producing individual ravioli, eliminating the need for the cook to individually prepare the dough, fillings, and assembly of each piece.

Futuristic Footwear: 3D Printed Shoes

Photo credit: Adidas

Shoes that perfectly fit your feet are no longer a dream. Brands like Adidas and Nike are employing 3D printing technology and AI to produce customized footwear, marrying comfort and style with eco-friendly materials. Even casual footwear companies are getting in on the action. Zellerfeld, a 3D-printed footwear company backed by the teams behind Tesla, SpaceX, PayPal, and StockX, has partnered with global artist Chris Brown to create a new 3D-printed slide called NAMI. The slide utilizes a sustainable and innovative material called ZellerFOAM, eliminating the need for manual labor and allowing for the production of a pair of shoes in mere hours.

A Step into the Future: 3D Printed Cars

Photo credit: Local Motors

3D printing is even transforming the automotive industry. Local Motors made waves when they unveiled Strati, the world's first 3D-printed car. The electric vehicle is constructed using 212 layers of ABS plastic reinforced with carbon fiber. This method can rapidly 3D print objects, which are then machined to precise specifications as needed. This enables Local Motors to quickly and freely produce car-sized structures with accuracy comparable to machined parts, all without the need for specialized forming tools.

A Creative Canvas: 3D Printed Fashion

Photo credit: Fredrik Robertsson

The fashion industry is also tapping into the potential of 3D printing. Designers like Iris van Herpen are creating stunning 3D-printed garments, reshaping the face of fashion. For example, her “Foliage” pattern dress utilizes a 3D printer capable of printing multiple materials at once to weave its fabric. At the 2022 Met Gala, four gowns created by her were showcased, each incorporating aspects of 3D printing methods. Her designs combine meticulously crafted digital 3D modeling with the more erratic characteristics of deformation found in analog processes.

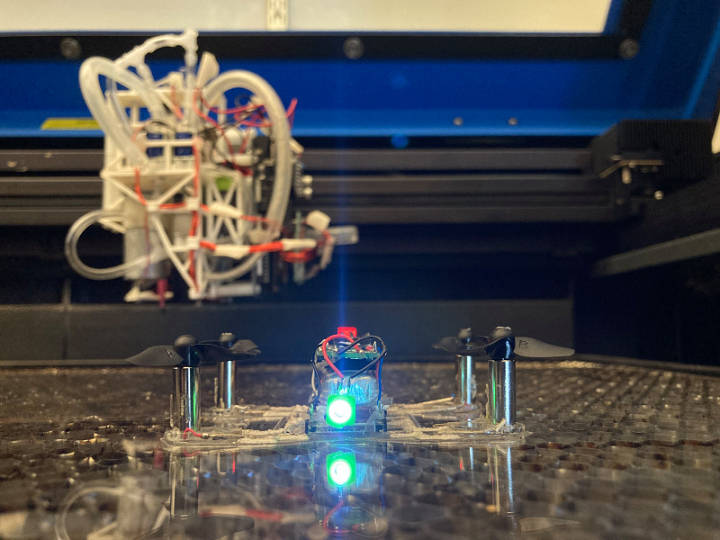

Taking Flight: 3D Printed Drones

Photo credit: MIT CSAIL’s LaserFactory

Drones are becoming an integral part of our lives, and 3D printing is playing a significant role. The ability to rapidly prototype and customize parts has led to innovations like 3D-printed drones from MIT CSAIL’s LaserFactory. LaserFactory's innovative system employs a system consisting of two integral components: a software toolkit empowering users to design personalized devices, and a hardware platform that brings these designs to life. By harnessing the capabilities of widely accessible manufacturing technologies like 3D printers and laser cutters, LaserFactory revolutionizes the process by seamlessly integrating these functionalities and automating the complete pipeline for generating structural geometry, printing traces, and assembling electronic components like sensors and actuators.

Beyond the Earth: 3D Printed Rocket Parts

Photo credit: SpaceX

SpaceX is making use of 3D printing to manufacture parts of their rockets, proving that the technology is ready for the most demanding tasks, even space exploration! With more than 85 percent of the rocket made of components created through 3D printing, this innovative approach allows for the assembly within a mere two-month timeframe, in stark contrast to the two years required for traditionally manufactured counterparts. 3D printing also offers significant advantages in terms of both speed and cost when producing prototypes, like scaled-down models for wind-tunnel testing. This additive process reduces waste substantially, while modifications can be easily implemented by reprogramming the 3D printer rather than going through time-consuming and costly retooling procedures.

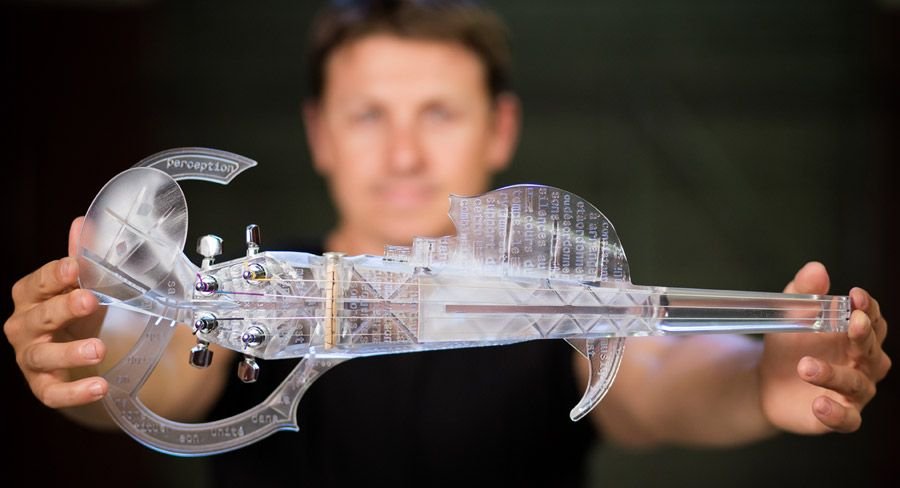

Sounds of the Future: 3D Printed Musical Instruments

Photo credit: Laurent Bernadac

Even the music industry is feeling the influence of 3D printing. The world's first 3D-printed violin, created by Laurent Bernadac, showcases the remarkable capabilities of additive manufacturing.

Debuting at the Acoustical Society of America's Conference in December 2022, the violin not only functions as well as traditional ones but also possesses the remarkable advantage of being produced at a fraction of the cost. Printing expenses for these 3D-printed instruments are as low as $7 per violin, with assembly costs under $30. With the typical retail price of approximately $500 for entry-level violins, these significant savings would make learning instruments more accessible than ever before.

Embracing a New Era: The Infinite Possibilities of 3D Printing

These revolutionary products bring to light the endless potential of 3D printing. This technology isn’t just about creating things; it's about pushing the boundaries of our imagination and making the impossible possible. As the world of additive manufacturing continues to expand, we can only wonder what boundaries will be overcome next.

About Tronix3D

Tronix3D is a leading contract-based Additive Manufacturing company dedicated to providing exceptional low-volume production and prototype parts for a diverse range of industries. Our comprehensive services encompass mechanical design and consulting, specifically tailored to the unique requirements of additive manufacturing. Leveraging cutting-edge printing technologies such as HP Multijet Fusion (HPMJF), Fused Deposition Modeling (FDM), and Stereolithography (SLA), we deliver high-quality, precision-engineered solutions for our valued clients in the robotics, energy, medical, and defense sectors. At Tronix3D, we pride ourselves on our commitment to innovation, quality, and customer satisfaction, ensuring that our partners receive the best possible results for their projects. Discover more about our services and capabilities at www.tronix3d.com.